Keeping it Cool & Clean

Advancements in technology have enabled major breakthroughs and discoveries that have shaped the modern world as we know it. Refrigeration is one of those – making certain environments habitable, creating spaces for life-saving discoveries, and elongating the shelf life of perishable goods (food/medicine) for global distribution. As we have designed refrigeration systems for these applications, we have taken a closer look at the impact of the systems on the environment, from energy consumption, greenhouse gas emissions, and global warming potential.

CREATURE COMFORT

Several studies have been conducted on the effects of room temperature on the occupant’s ability to effectively perform expected functions: learning/ productivity. Each has concluded that environmental discomfort contributes to distractions and occupant performance. As a result, air-conditioning is becoming a standard application within educational and workplaces – adding to the energy consumption and environmental effects of the building.

To counter the impacts of cooling the space, teams are balancing the tradeoffs between centralized and distributed HVAC systems. The concentration of equipment to deliver the conditioned air and volume required is translating to a more distributed configuration with a heat pump solution to offset the building’s EUI.

GROCER APPLICATION

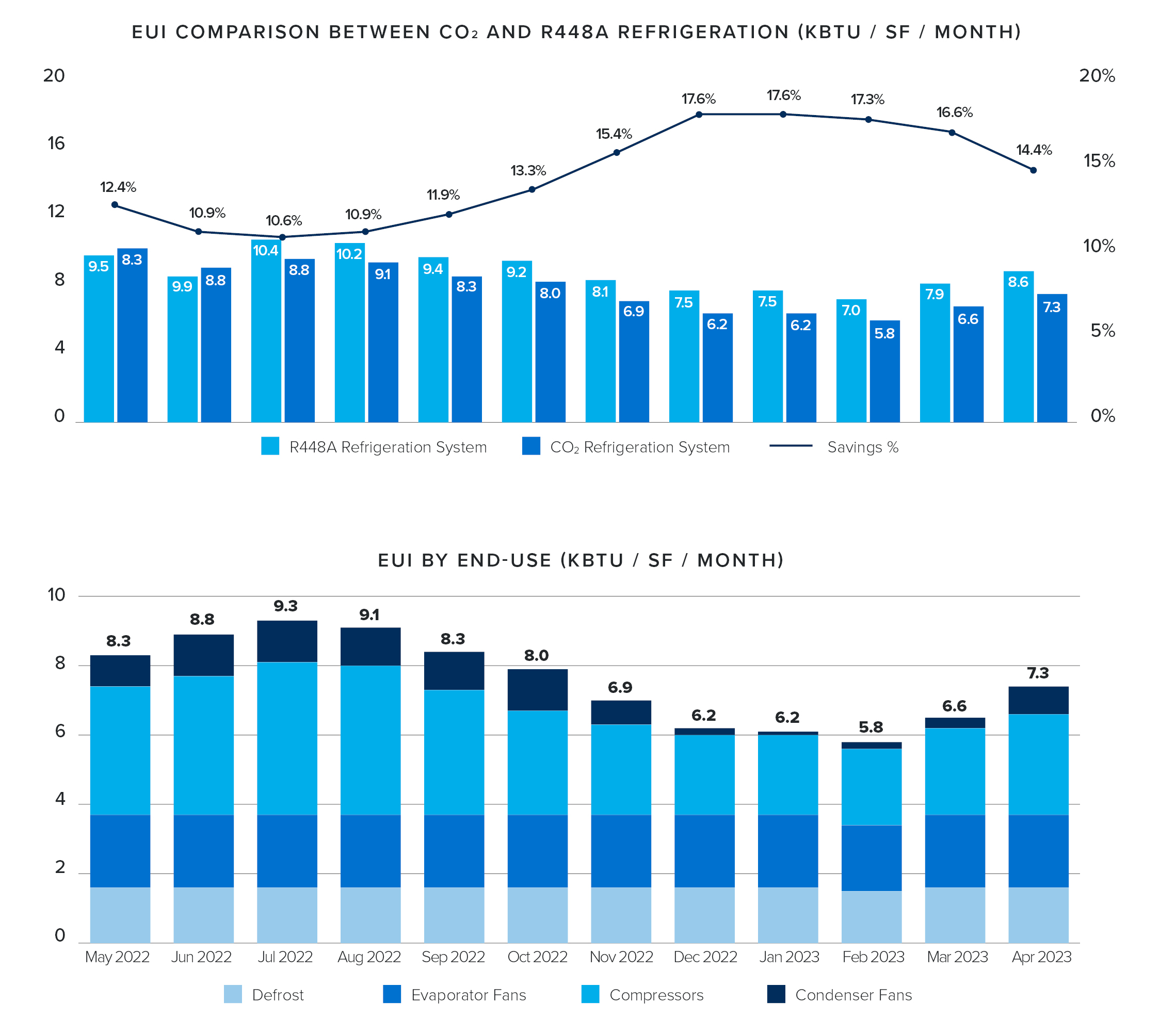

Once seen as a ‘process load’ and exempt from most energy codes, in recent years grocery refrigeration has started to experience the same regulations as other energy-intensive mechanical systems. Over the years we have developed methodologies to help our clients achieve energy savings.

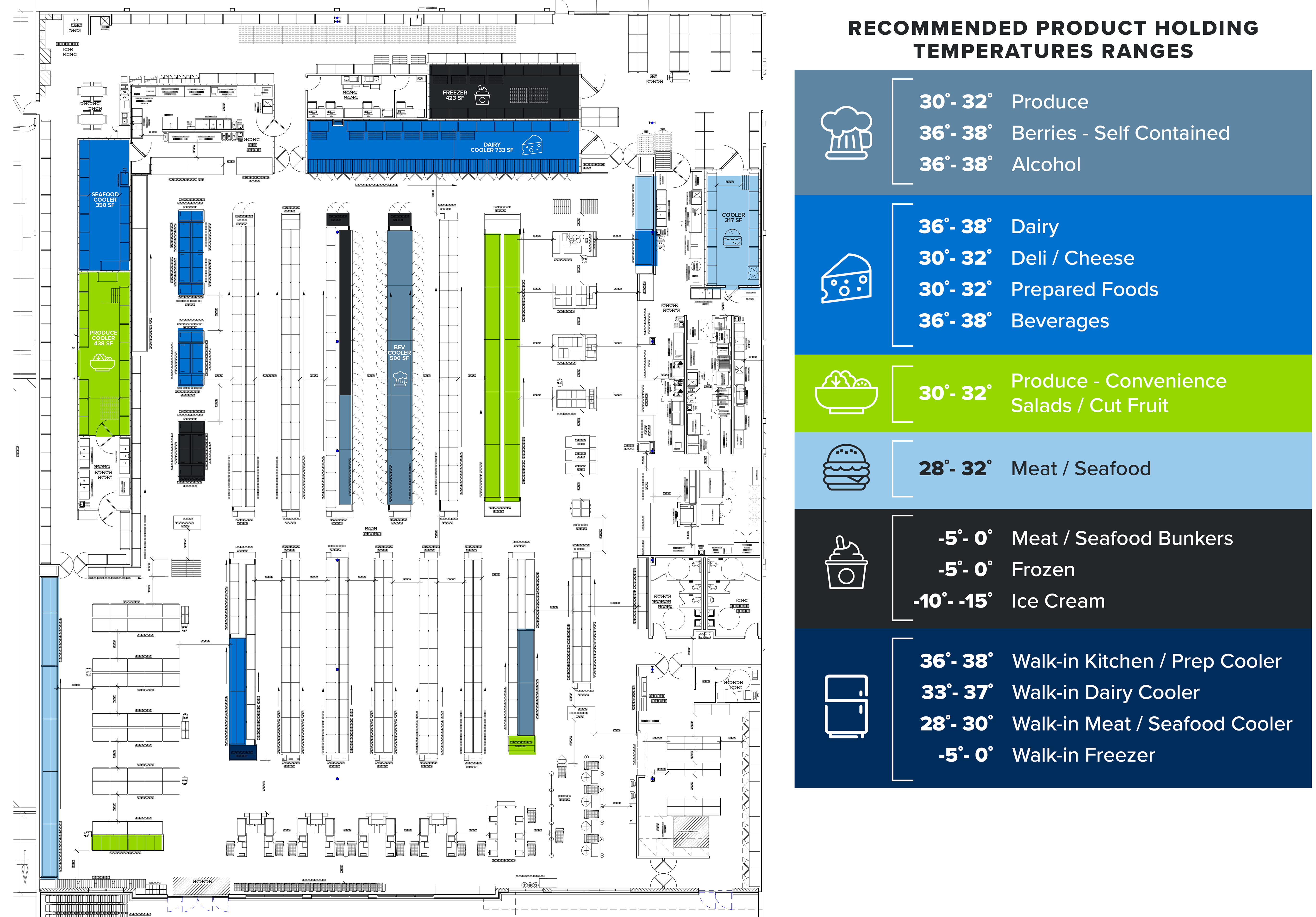

One way we help our grocery clients design the most efficient system starts at the beginning of the store layout process. Each food category (produce, dairy, meat, deli, beer, ice cream, etc.) needs to be held at a different temperature to maintain freshness and extend shelf life. For a recent grocery start-up, we assisted the store designers in selecting the most efficient and appropriate refrigerated display cases for the application. Some of these cases had doors, where traditionally they did not, which helped to further reduce the refrigeration energy needed. We then grouped these food categories in a way that pairs common temperatures together allowing the refrigeration rack to operate at as high a suction temperature as possible. This in turn reduces the work the compressors are required to do and directly reduces the overall energy input to operate the system.

In the realm of refrigeration, there is a term "super cold" or cold as ice cream from the freezer case. These spaces require -15° F or colder to protect product/specimen. In the case of ice cream, so it can be transported home without melting (or studied under a microscope). Refrigerants are available that meet several states' GWP <150 standard for these super cold applications.

In the realm of refrigeration, there is a term "super cold" or cold as ice cream from the freezer case. These spaces require -15° F or colder to protect product/specimen. In the case of ice cream, so it can be transported home without melting (or studied under a microscope). Refrigerants are available that meet several states' GWP <150 standard for these super cold applications.

MEDICAL LAB APPLICATION

Temperature controls play a part in the research and discovery of medical advancements. To understand how temperature impacts certain ailments, like diabetes, environmental controls and data capture are critical to identifying correlations. Similarly, tight temperature controls (1° +/- rise/fall rate with capabilities to hold temperature and humidity settings) are required for specimen storage and apparatus operations.

We’ve designed several labs like these for private and public R&D firms, where temperature regulation is critical to observing physiological outcomes, maintaining the integrity of the stored product, and maintaining apparatus warranties.

We are vigilant about understanding the comfort and apparatus temperature control requirements within these spaces. We bridge the program requirements with maintenance and operations considerations as the refrigeration systems are identified for each unique application – which can be as many as six in some biosafety labs.

APPARATUS LAB APPLICATION

The equipment that supports supplementary systems generates what is known as a process load. Much like the vacuum system in a medical application that generates heat in its operations, a coolant is needed to keep the system from overheating.

This is also true of testing labs, where large hydraulic systems with as much as 50 hp motors are used on vibration tables to test apparatuses (like microscopes, home security cameras, packaging, etc.). The motors generate a significant amount of heat and require a supplemental cooling system to offset the processing load.

Critical to designing the cooling system for these applications is knowing the operating load, the temperature criteria, and which refrigerant is best suited for the system. Cognizant of the global warming potential (GWP) of some high-temperature systems, we are working with stakeholders to right-size the overall system to align with lower GWP options.

REFERENCES

https://files.eric.ed.gov/fulltext/EJ1152622.pdf

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4591743/

https://www.nea.org/advocating-for-change/new-from-nea/its-getting-hot-here-without-air-conditioning-students-and-staff-suffer

https://www.sitelogiq.com/blog/effect-classroom-temperature-student-performance/