Proven

Matching the rapid pace of technology has been the bar that measures the creativity, responsiveness, and competitiveness of a firm. We strive to elevate that bar at each opportunity.

Supporting industry visionaries to meet aggressive schedules, evolving business models, progressive conservation commitments, and new market penetration goals, we have been on the ground floor of turnkey program development. We developed standards, prototypes, and ambitious schedules under extreme conditions.

We have fueled that evolution through our experience, approach to client advocacy, and adaptive nature. Drawing from the best practices of design and construction, we uphold project key performance indicators (KPI) through design, commissioning, and energy conservation solutions.

REAL-TIME PROJECT MANAGEMENT

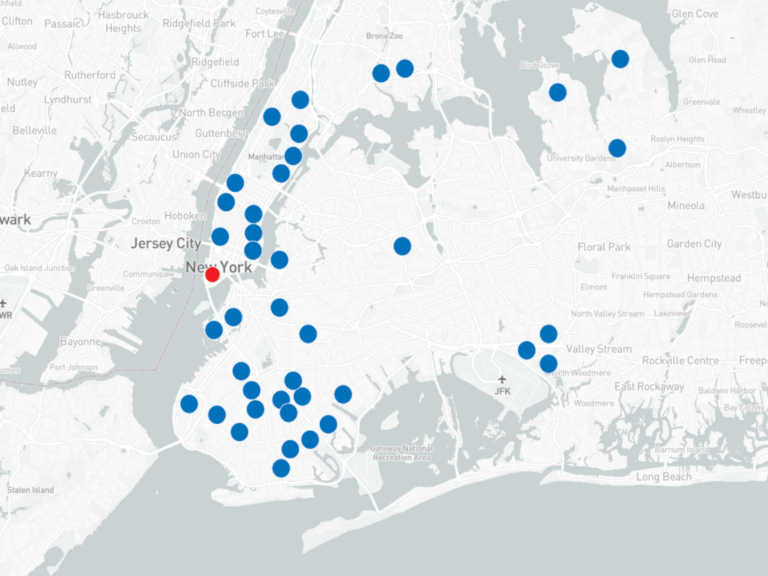

Within a 5-month period, the acquisition team was responsible for migrating 124 financial retail sites located throughout New York and New Jersey onto the new corporate backbone infrastructure to reflect the new ownership.

Like the flip of the switch, the execution of the project was critical to its success despite short lead time, scheduling over the holiday season, and logistical detours.

Our project managers worked closely with product manufacturers, distributors, contractors, and logistics teams to ensure the timely ordering and delivery of products and services. We carefully planned and monitored the design time, taking into consideration the contractor’s availability and the need to create the greatest efficiency while constructing in the New York metropolitan area, 4 months after 9/11.

BRIDGING ENTERPRISE AMBITIONS

A ground-breaking effort for the Department of Social and Health Services to upgrade multiple campus fire alarm systems throughout the state – east, and west.

Legislators wanted to evaluate the opportunity to award the installation under a single contract, a challenge under procurement practices. Balancing the technical and non-technical attributes of this project, we developed a plan to optimize the available funds and authored a report on how to address the complexities of statewide public work contracting. The project received additional funding to complete the ambitious undertaking, while the existing budget was optimized through strategic, discrete scopes of work that would offer the greatest benefit to the state.

The upgrade was to encompass 150+ buildings across five state facilities with legacy technology ranging from 10-40+ years old. Upon completion, the project represents significant improvements to life safety across five facilities, improved fire alarm communications, reduced response times, replacement of outdated systems, and reduced maintenance costs.

IMPROVING BUILDING PERFORMANCE

The energy-intensive operations of this facility require tight temperature tolerances and full redundancy, much like a chip manufacturing plant or mission-critical data center.

Energy and water conservation strategies were evaluated at the onset of the project, as well as the exact site location for long-term cost control.

Requiring over 100,000 gallons of water a day for peak load, the annual operational cost of the water system was 53% less than over an air-cooled system and required 45% less energy to operate annually. However, additional savings were available through site selection, as the rates between the five possible water and three electrical utility districts varied. The water costs differed more significantly than the electric rates with demand charges included. The heavy electric use allowed the owner to negotiate a lower rate for electricity.

2021 American Institute of Architects (AIA) Chicago Distinguished Building Award

Program Spaces

53,483 sf

23,705 sf manufacturing

11,621 sf administrative support space

9,000 sf mechanical and electrical infrastructure

3,029 sf R&D floor

ISO-7 cleanroom

System Attributes

9 MW power load

waterside economizer

fluid-coolers

water to water chillers

variable-primary packaged pumping system

five specialty gases and compressed air

hydronic central plant system // deionized water system